The key function of the EyeVision 3D software is the capture and evaluation of 3D-images (point clouds). Based on the point cloud, the EyeVision 3D software has several commands for:

- Detect and count objects

- Detect errors

- Carry out different metrology operations

EyeScan 3D-sensors

With the 3D-camera system EyeScan 3D, EVT offers the EyeVision users easy access to the third dimension.

3D-Sensors are applicable in all industries, such as for:

- Quality control

- Robot control and guidance

- µ-accurate metrology

EyeScan 3D means for the user:

- An already calibrated 3D-sensor – based on laser triangulation, shape-by-shade, Time-of-Flight, or stereo vision

- The complete evaluation software EyeVision 3D is supported and can be programmed via drag-and-drop function

How EyeVision 3D can be used:

- Optimizing the production process

- Improving quality control

- Reducing production costs

Applications

- Tire Production- For tire production, a 100%-quality control is indispensable. A 3D inspection also detects the black print on a black tire. At the same time also other surface defects can be detected.

- Weld Seam Inspection- EyeVision 3D checks for weld width and length, countersink free finish, weld seam joint or collapses, unequal sidedness, holes, and surface pores.

- Inspection of Adhesive Applications- Noncontact and nondestructive inspection immediately after the application of the adhesive bead. Suitable for all glues and surfaces. EyeVision 3D recognizes flaws such as e.g.: discontinuity, thickening, and position errors of adhesive beads.

- Sealing Compound Inspection- EyeVision 3D software inspects if the sealing compound is applied correctly and checks the positioning of the sealing compound. EyeVision and the EyeScan 3D Sensor guide the robot.

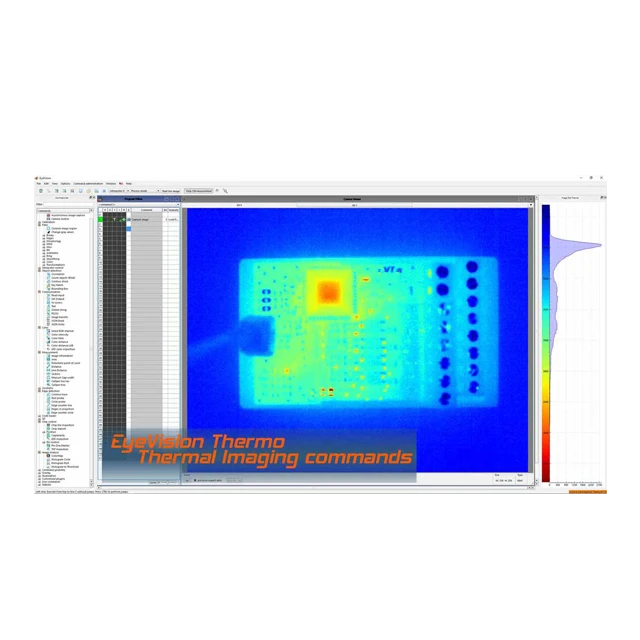

- PCB Inspection- EyeVision 3D inspects at the soldering process and checks the component parts for alignment, position, presence.

- Smart Phone Inspection- EyeVision 3D software inspects small-format substrates as e.g. for smartphones. Measures fixed component parts and wavelength-dependent transmissions of filter layers on glass substrates.

- Grocery Inspection- EyeVision 3D scans the size and shape of e.g. fruits and sorts them accordingly afterward. This process prevents rejection.

- Part Inspection- EyeVision 3D software checks on shape-defects such as e.g.: cylindrical form, corrugation, circularity. Additionally geometrical dimensions e.g.: diameter, height, width, etc.

- Cast Metal Inspection- The 3D sensor scans cast metal parts and compares the scanned image with the CAD-data. EyeVision 3D inspects the shape and measurements during the production process.

- Gap Inspection- EyeVision 3D software inspects different gap types e.g.: simple gap, projection-gap, the gap with bottom, advanced gap.

- Bin Picking- EyeVision 3Dcaptures component parts in every position and rotation. Reacts on position changes of the objects. EyeVision 3D allows complete usage of the robot line.

- Area Scan- EyeVision 3D software can scan large surfaces and can display it undistorted with the 3D Unrolling command, without the need of an axis or robot.