EVT Smart Scratch Inspector System

Highlights

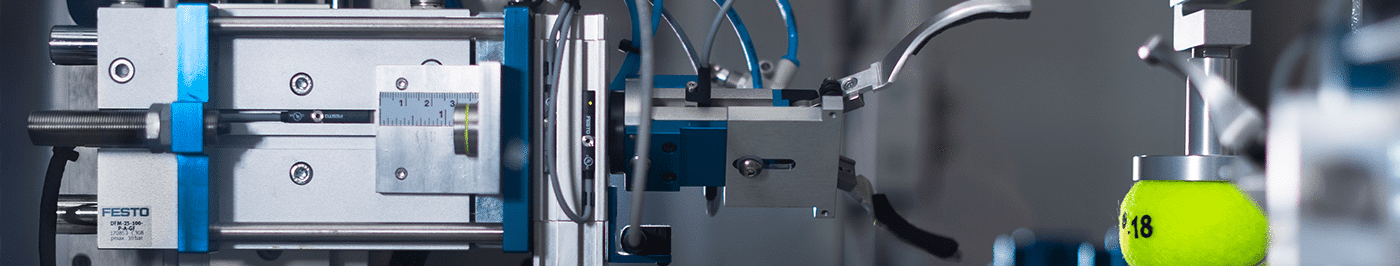

With the intelligent, Machine Learning-based EVT Smart Scratch Inspector System, the detection of defects on surfaces is very easy. Based on a Deep Learning method, the Inspector detects any disturbances on the surface, similar to the human eye. The system is based on the EyeVision software and is easily adapted to your applications. The hardware includes the EmSys computing unit and an industrial camera of the supported makers such as e.g. Allied Vision Technologies, Basler, Baumer, Teledyne Dalsa, Flir, etc.

Ready-to-use System

The EVT Smart Scratch Inspector System is ready-to-use. The smart system has everything to integrate it directly into a machine. It has 8 in- and 8 outputs to control the machine or to communicate with the PLC and is also equipped with a Profinet option. The system has LED outputs to connect the illumination to the Scratch Inspector.

EVT Smart Scratch Inspector System Features

| Based on Machine Learning Algorithms | Interfaces: GigE, USB, RS232, RS485 |

easy integration into:

|

communication protocol for:

|

| Stand-alone system | Headless system |

Tracker-Protocol

Via the hardware interface, the system can communicate with a tracker-system as well as SCADA or PLC. Different tracker boards and systems can be integrated into the inspection process with the tracker-protocol.

Stand-lone or Headless System

The stand-alone-system is available with a user interface and can be set up locally. The headless system is programmed remotely from the master computer to upgrade already existing facilities.

Industry 4.0 Compatible

Errors in the surfaces are either reported directly via I/O signal or an ejector is activated. Furthermore, information can be sent via the Profinet interface to the system control. Therefore the smart sensor is easily integrated into an Industry 4.0 environment. A database connection and a detailed statistic allow the user to directly display the detected errors.